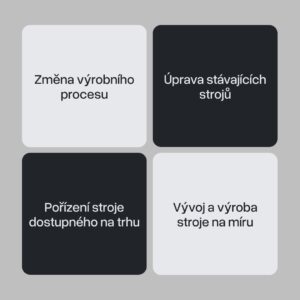

In the framework of initial production scan we often find that it makes sense for companies acquisition of available technologywhich is already on the market. If there is a machine that meets your needs, there is no need to invest time and money in developing it from scratch.

Such a decision can significantly speed up return on investment and take production one step further.

How does the technology selection process work?

Buying a machine is not enough to get the maximum benefit. You need to ensure that fit into your production:

-

🔍 Choosing a suitable supplier - we check quality, references and service support.

-

🔄 Integration into existing technologies - we check compatibility and connection to your processes.

-

📐 Layout preparation - we design the ideal machine location for efficient operation.

-

🧪 Testing in practice - first the test is carried out at the supplier (FAT), then directly at your factory (SAT).

Technology as a puzzle piece

Technology alone is not enough. If it doesn't fit into your processes like the last piece of the puzzlecan be more trouble than it is worth - for example, complicated operation, frequent downtime or unnecessary maintenance costs.

When was the last time you investigated this?

There may already be a solution to your problem on the market today. You just need to find it and incorporate it into production.

👉 Thinking about new technology?

Let us know - we'll choose the right solution and take care of a smooth integration.