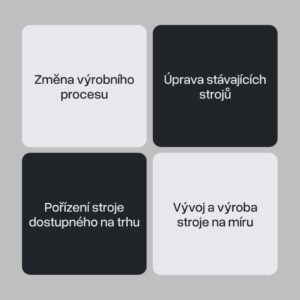

When conventional technology is not enough

Situations arise in production where no available equipment or modification can provide the required performance, quality or process stability. At such times, the right step is to develop a unique customized machine.

How we proceed with the design

The development starts with a conceptual study that verifies whether it makes sense to develop the project further.

The study includes:

-

Verification of technical feasibility - we assess whether the solution can be implemented and what risks need to be eliminated.

-

Virtual simulation of ergonomics and operation - Using virtual reality tools, we test human-machine interaction before production.

-

Prototype testing of key principles - we validate critical parts of the process on prototypes to ensure functionality.

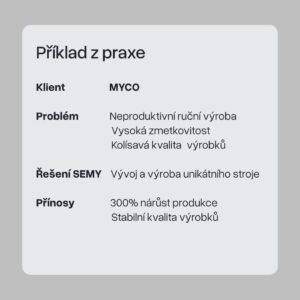

A practical example: MYCO

For the client MYCO we have developed a unique production machine to replace the original manual process. This was not only inefficient, but also showed fluctuating quality. Thanks to automation, today the company:

-

Produced by triple of the original volume,

-

each product has consistent quality,

-

the operator focuses on control and added value instead of routine work.

When is a customized machine suitable for you?

If you are facing a similar problem, customized development may be the solution. Our services include calculation of return on investmentto see how quickly the new machine will pay for itself.

👉 Wondering in which part of your production could a customized machine bring the biggest effect? We'd be happy to help you with that - get in touch.