Production automation starts with the right analysis. That's why at SEMA we recommend the first step - initial scan of production processes. Thanks to it, we can reveal where companies are missing out on time, capacity and money.

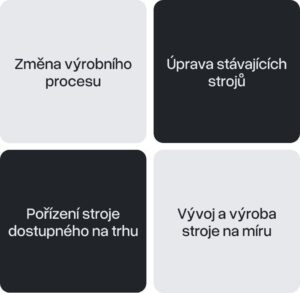

It may come as a surprise that one of the most common recommendations is not to acquire new technology, but to change in the organisation of work and the production process itself.

Optimising production without large investments

Adjustments in production often do not require millions of dollars of investment in machinery. On the contrary - small changes can yield major results:

-

Rearrangement of the hall layout - shorter journeys, faster logistics.

-

Streamlining material flow - less unnecessary relocation.

-

Adaptation of workplaces to 5S or ergonomics - increased comfort and operator performance.

-

Elimination of downtime and non-value added activities - more time for what's important.

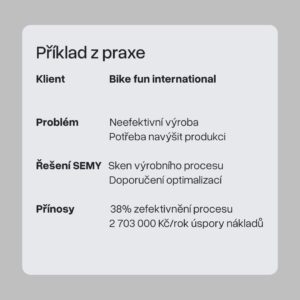

A real example from practice

For one of our clients, we have achieved the following with these steps:

-

process acceleration of 38 %,

-

cost reduction of more than CZK 2 million per year,

-

namely completely without new investment in machinery.

Why do companies often overlook these steps?

Because they seem "too easy". In practice, however, it turns out that just basic changes in the production organisation have the greatest impact.

If you've already adjusted your company's processes but the results are still not to your liking, it's worth following this path. Our solutions combine process adjustments with automation to keep investments to a minimum and the effect to a maximum.

Optimisation doesn't have to mean huge investments. Often, it's enough to look at production with new eyes and change processes that hinder efficiency.

👉 Do you want to know how to make your production more efficient?

Contact us - we will design a tailor-made solution for you.