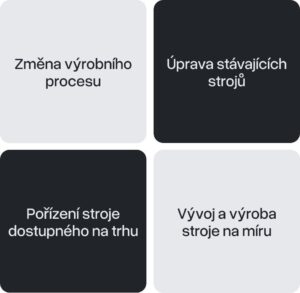

When it comes to streamlining production in a manufacturing company, most managers think of buying new technology. But in practice, it often turns out that a great deal of potential lies directly in machines that you already have.

Therefore, the second most common area of recommendation based on our Initial production scan, it tends to be modification of existing machines - not their replacement.

What are the benefits of machine modifications?

-

✅ Better user-friendliness - machines help the operator instead of hindering him.

-

📉 Lower scrap rate, higher production - adjustments improve accuracy and reliability.

-

⏱️ Less routine, more performance - Operators spend less time on non-value-added activities.

-

🛠️ Easier setup, maintenance and service - simpler work means fewer mistakes.

-

🤖 AI support option - Predicting faults, guiding operators or recommending process modifications.

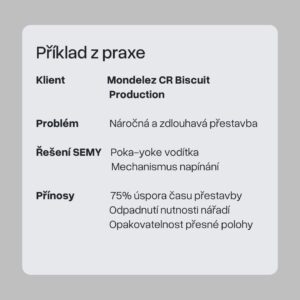

A real example from practice

For one client, we performed modifications of older conveyors. Thanks to this:

-

the operator does not spend time on complicated settings,

-

devoted to actual production,

-

and the whole process is significantly more productive.

Without buying new machines, only with clever modifications.

Why is it worth starting with machine modifications?

Buying new technology is always a big investment. But if you use the potential you already have in production, you can achieve:

-

faster returns,

-

lower costs,

-

and better production performance - with minimal investment.

Your machines can be your ally - or your brake. It depends on how you work with them.

👉 How's yours? Do they help the operator or do they give her a job?

Contact us and we'll show you how to eliminate non-value-added activities.