Inefficiencies in production take many forms

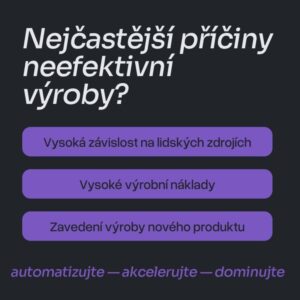

Companies turn to us with various problems that hinder their production. Nevertheless, there are three most common reasons when optimization makes sense:

-

High dependence on human resources

When production is too tied to manual labour, bottlenecks, quality fluctuations and capacity problems arise. -

High production costs

The rising cost of energy, materials and labour is forcing companies to look for savings - automation and more efficient processes are one way. -

The need to introduce automated production of a new product

For new projects, it is often not possible to rely on existing equipment or manual processes. Automation helps to set up stable and scalable production from scratch.

How we help

If the cause of the problem lies in the machinery or the organisation of the work, we offer a complete solution:

-

initial analysis of production and recommendation of the appropriate procedure,

-

design, development and production of a single-purpose machine,

-

follow-up service and support.

The goal is always one: increase production efficiency and strengthen the company's competitiveness in the long term.

Every company has a different starting point. The important thing is to start - and look at production to uncover the greatest room for improvement.